Charge pipes, made from lightweight materials like aluminum, are crucial components in modern vehicles' charging systems, optimizing airflow dynamics and minimizing pressure drops for enhanced engine performance. They directly connect to boost controllers, enabling precise control of air intake for better combustion and improved throttle response. Integrating seamlessly with other performance upgrades, charge pipes play a versatile role in overall vehicle enhancements. Together, charge pipes and boost controllers optimize engine performance and efficiency in turbocharged vehicles by delivering cool, dense compressed air and regulating turbocharger pressure, resulting in increased power, better fuel economy, and superior driving experience.

“Uncover the intricate dance between charge pipes and boost controllers, two vital components in the quest for enhanced engine performance. This article explores the fundamental roles of charge pipes in delivering compressed air, and how they seamlessly integrate with boost controllers to optimize power and efficiency. By understanding these interactions, automotive enthusiasts can gain insights into the technology behind turbocharged engines, leading to better overall vehicle dynamics.”

- Understanding Charge Pipes: The Basic Functionality and Role in Engine Performance

- Boost Controllers: Their Operation and Integration with Charge Pipes

- The Interplay Between Charge Pipes and Boost Controllers: Enhancing Engine Power and Efficiency

Understanding Charge Pipes: The Basic Functionality and Role in Engine Performance

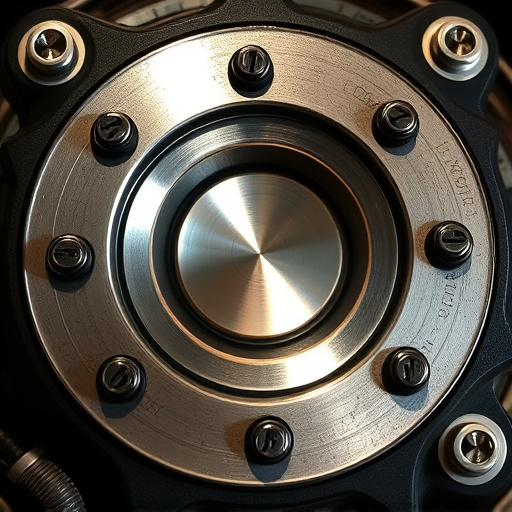

Charge pipes are a critical component in the engine’s charging system, responsible for delivering compressed air to boost controllers. These pipes serve as efficient conduits, ensuring a consistent and high-pressure flow of air from the compressor to the turbocharger or supercharger. By facilitating this process, charge pipes play a pivotal role in enhancing engine performance and power output.

In modern vehicles, especially those equipped with turbo or supercharged engines, charge pipes are designed to optimize air flow dynamics. They are often crafted from lightweight materials like aluminum, which reduces restrictions and minimizes pressure drop across the system. This direct connection between the boost controller and the engine allows for precise control of air intake, enabling better combustion and improved throttle response. Furthermore, integrating charge pipes with coilover kits or upgrading brake rotors and pads won’t affect their functionality, making them a versatile part of an overall performance-enhancing package.

Boost Controllers: Their Operation and Integration with Charge Pipes

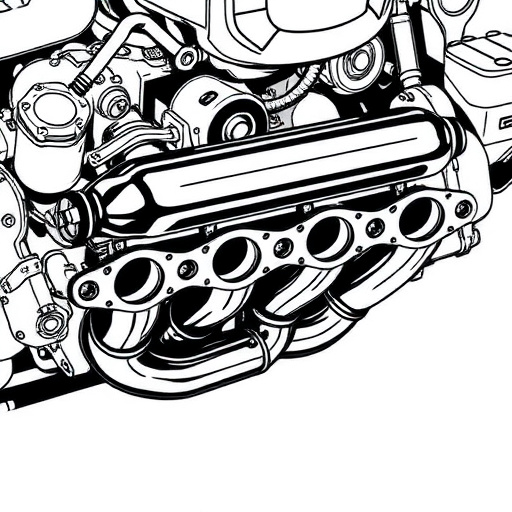

Boost controllers play a pivotal role in enhancing vehicle performance, especially for those with turbocharged or supercharged engines. These advanced devices manage and regulate boost pressure, ensuring optimal power delivery. They work by monitoring manifold absolute pressure (MAP) sensors and adjusting the amount of compressed air entering the engine. This precise control is crucial for achieving consistent and reliable performance gains, particularly in vehicles equipped with charge pipes.

Charge pipes, integral components of forced induction systems, include air intake systems and cold air intakes. They facilitate the direct flow of cold, dense air from outside the vehicle into the engine. By integrating boost controllers with these charge pipes, drivers can unlock the full potential of their vehicles. The controller optimizes air flow, ensuring that the engine receives the perfect blend of fuel and oxygen for enhanced combustion, resulting in improved throttle response, higher horsepower, and better torque—all without compromising on efficiency or reliability, even under extreme driving conditions.

The Interplay Between Charge Pipes and Boost Controllers: Enhancing Engine Power and Efficiency

The interaction between charge pipes and boost controllers is a key aspect in enhancing engine performance and efficiency, particularly in turbocharged vehicles. Charge pipes, also known as intake manifolds or charge air coolers, play a pivotal role in delivering compressed air to the engine. They ensure that the air entering the combustion chamber is cool and dense, allowing for more efficient burning of fuel.

Boost controllers, on the other hand, regulate the amount of boost pressure applied to the engine by the turbocharger. By precisely controlling this pressure, they optimize the engine’s power output while maintaining stability and efficiency. The seamless integration of charge pipes and boost controllers enables a more consistent and powerful performance across various engine speeds, translating to improved acceleration and overall driving experience—a true testament to the advanced engineering behind these components, enhancing not just power but also fuel economy, especially in high-performance vehicles.

Charge pipes play a pivotal role in enhancing engine performance by efficiently transporting compressed air, facilitated by their seamless integration with boost controllers. This interplay optimizes power output while improving fuel efficiency, making them essential components in modern automotive engineering. Understanding this relationship is crucial for tuning and optimizing high-performance engines, ensuring they reach their full potential on the road.