Charge pipes, strategically designed components in turbocharged and supercharged vehicles, enhance engine performance by efficiently transporting compressed air from boost controllers to intake ports. Their lightweight materials and precise engineering minimize restrictions, maximize flow rates, and ensure a direct pathway for aerated air, optimizing combustion and power output. Boost controllers, critical for managing boost pressure, work with charge pipes to deliver ideal air intake based on real-time engine conditions, promoting fuel efficiency and reduced emissions while enhancing throttle response and overall vehicle performance.

“Unravel the intricate relationship between charge pipes and boost controllers, essential components in high-performance vehicles. This article explores the symbiotic interaction that enhances engine efficiency. We begin by understanding the charge pipes‘ role in directing compressed air, followed by an insight into boost controllers‘ dynamic operation. The core connection between these systems is delved into, revealing how their integration optimizes performance, a crucial aspect for automotive enthusiasts and engineers alike.”

- Understanding Charge Pipes: Function and Design

- Boost Controllers: Role and Operation Mechanism

- The Interconnection: How They Enhance Performance

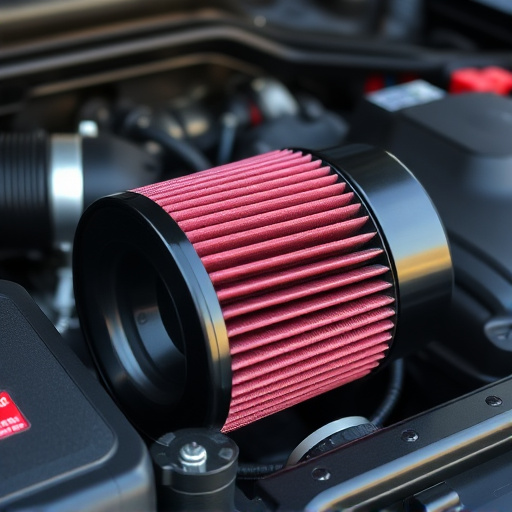

Understanding Charge Pipes: Function and Design

Charge pipes, a critical component in many high-performance vehicles, play a pivotal role in enhancing vehicle performance. These specialized tubes are designed to efficiently transport compressed air from a boost controller to various intake ports across an engine. Their primary function is to ensure a consistent and robust supply of aerated air, which is essential for optimizing combustion and boosting power output, particularly in turbocharged or supercharged engines.

The design of charge pipes incorporates lightweight materials and precise engineering to minimize air restrictions and maximize flow rates. They are strategically positioned within the vehicle’s intake system, connecting the boost controller to specific cylinder ports, ensuring a direct and uninterrupted pathway for compressed air. This configuration enhances engine breathing capabilities, allowing for improved throttle response and overall vehicle performance, especially under demanding driving conditions where quick acceleration is crucial.

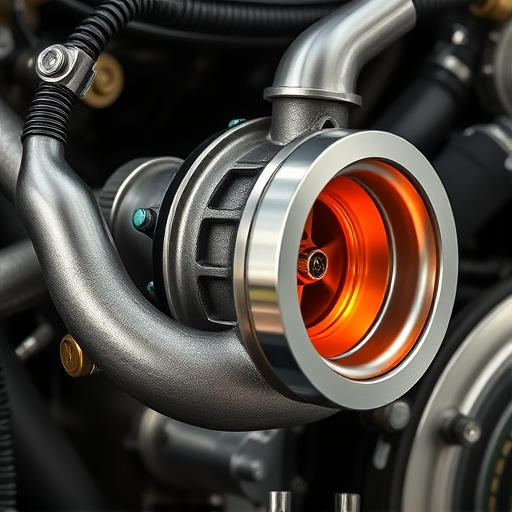

Boost Controllers: Role and Operation Mechanism

Boost controllers play a pivotal role in managing and optimizing engine performance, particularly in vehicles equipped with turbocharged or supercharged engines. These advanced electronic devices act as the brain behind the power generation process, meticulously controlling the flow of compressed air into the combustion chambers. By precisely regulating the amount of boost pressure applied to the engine, boost controllers ensure optimal burning of fuel, leading to increased horsepower and torque output.

The operation mechanism of a boost controller involves intricate sensors and actuators that monitor various parameters like manifold pressure, engine speed, and temperature. Based on these inputs, the controller adjusts the position of the wastegate valve in the turbocharger or supercharger, allowing for precise control over air intake. This real-time adjustment ensures that the engine receives the ideal amount of boost, maximizing performance while maintaining efficiency across different driving conditions, especially during acceleration or high-speed maneuvers. Efficiently managing boost pressure also contributes to better fuel economy and reduced emissions, making boost controllers an essential component in modern automotive engineering.

The Interconnection: How They Enhance Performance

The interaction between charge pipes and boost controllers is a key aspect that enhances vehicle performance, especially in modified cars and high-performance vehicles. These two components work synergistically to optimize engine efficiency and power delivery. Charge pipes, responsible for delivering compressed air from the turbocharger or supercharger to the engine, are designed to provide a constant, efficient flow of air. They ensure that the boost controller receives accurate air mass data, which is crucial for precise control of the boost level.

Boost controllers, in turn, regulate the amount of boost applied to the engine based on various inputs, including air temperature, pressure, and engine load. By seamlessly integrating with charge pipes, these controllers can maintain optimal air-fuel ratios, enhancing both power output and torque. This interconnection ensures that intake components, such as the turbocharger or supercharger, function at peak efficiency, resulting in improved throttle response and overall driving experience—a true game-changer for vehicle performance enthusiasts.

Charge pipes and boost controllers work in tandem to significantly enhance vehicle performance. By efficiently managing and distributing compressed air, charge pipes ensure optimal boost levels, while boost controllers regulate this process, providing precise control for improved engine response and efficiency. This integration is a key component in modern automotive engineering, allowing vehicles to deliver powerful performances while maintaining fuel efficiency.