Charge pipes, advanced engineering components, revolutionize automotive and aerospace performance by optimizing airflow. They direct cold, dense air from external sources into combustion chambers, boosting torque and fuel efficiency. In aerospace, they enhance engine combustion, improve fuel efficiency, and reduce emissions. Engineers design charge pipes for structural integrity while minimizing flow restrictions, integrating seamlessly with existing systems. Future advancements in materials and manufacturing promise even better performance, weight reduction, and efficient packaging for cleaner, more powerful vehicles.

“Enhance aerospace performance with charge pipes—innovative systems revolutionizing air density and pressure regulation. This article explores the fundamental concept, delving into how these pipes optimally deliver compressed air for various applications. From their benefits, such as improved efficiency and reduced weight, to crucial design considerations, we dissect the future prospects of integrating charge pipes in modern aviation. Understanding this technology is pivotal for aerospace engineers aiming to optimize aircraft systems.”

- Understanding Charge Pipes: The Concept and Its Basic Functionality

- Benefits of Implementing Charge Pipes for Aerospace Applications

- Design Considerations and Future Prospects in Integrating Charge Pipes

Understanding Charge Pipes: The Concept and Its Basic Functionality

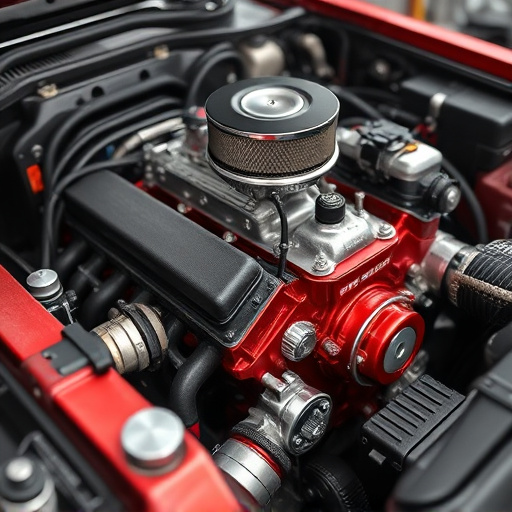

Charge pipes, a relatively modern innovation in automotive engineering, are designed to significantly enhance engine performance by optimizing airflow. These components are part of what’s known as a charge cooling system, which aims to increase both air density and pressure within an internal combustion engine. By facilitating a smoother and denser flow of air into the engine, charge pipes offer several advantages, including improved torque output and fuel efficiency.

The basic functionality revolves around directing cold air from external sources, such as a dedicated cold air intake system or even the engine’s own cooling radiators, directly into the combustion chamber. This direct route minimizes temperature increases along the intake pathway, ensuring that the air remains cooler and denser when it reaches the engine. Unlike traditional air filter kits, which can restrict airflow, charge pipes are designed for maximum airflow efficiency, allowing for enhanced performance brakes and overall vehicle responsiveness.

Benefits of Implementing Charge Pipes for Aerospace Applications

Implementing charge pipes offers significant advantages for aerospace applications, enhancing performance and efficiency across various systems. By optimizing air delivery, these pipes ensure a steady and dense flow of compressed air, directly impacting engine combustion processes. This results in improved fuel efficiency and reduced emissions, key considerations for aircraft design and environmental sustainability.

Moreover, charge pipes play a crucial role in integrating and managing high-pressure air systems, including suspension components and brake components. Their efficient design minimizes pressure drops, ensuring optimal performance of muffler tips and other critical components. This streamlined approach not only improves overall system effectiveness but also reduces weight, contributing to enhanced aircraft agility and maneuverability.

Design Considerations and Future Prospects in Integrating Charge Pipes

The design considerations for charge pipes are multifaceted, with engineers balancing multiple factors to achieve optimal performance. Key aspects include material selection, pipe geometry, and fitting configurations to minimize flow restrictions while ensuring structural integrity under high-pressure conditions. Integrating charge pipes seamlessly into existing vehicle systems also demands careful consideration of space constraints and compatibility with other components like muffler tips, suspension kits, and brake rotors.

Looking ahead, the future prospects for charge pipes are promising as advancements in materials science and manufacturing techniques open up new possibilities. Lightweight composite materials could further enhance performance while reducing overall vehicle weight, while innovative pipe designs optimized through computational fluid dynamics (CFD) simulations promise improved air flow rates and more efficient packaging. As engine technologies evolve, charge pipes are poised to play a pivotal role in enabling cleaner, more powerful, and more fuel-efficient vehicles.

Charge pipes, with their innovative design and functionality, offer a promising solution to enhance air density and pressure in aerospace applications. By efficiently compressing and directing airflow, these pipes can significantly improve engine performance and overall aircraft efficiency. As the technology continues to evolve, further research into design considerations will enable engineers to optimize their integration, making charge pipes an indispensable component in future aviation advancements.