Charge pipes, crucial for turbocharged engines operating at high RPMs, enhance performance by efficiently delivering compressed air from turbochargers to intake valves. They minimize restrictions, maximize airflow, and improve throttle response, reducing turbo lag and boosting fuel efficiency. Designed through advanced CFD simulations, custom charge pipes made of lightweight materials like aluminum or carbon fiber ensure optimal air delivery. Strategic integration of high-performance air filters further enhances efficiency. Charge pipes have proven effective in real-world applications, delivering significant horsepower gains and improved torque when paired with suspension kits and advanced tuning, setting new standards for high-RPM turbo performance.

“Unleash the full potential of your high RPM turbo with charge pipes—essential components revolutionizing automotive performance. This article explores the art and science of charge pipes, their pivotal role in enhancing turbo efficiency, and their impact on engine output. From understanding the fundamentals to designing for optimal performance, we delve into how these sleek conduits contribute to exceptional real-world results. Discover the success stories behind charge pipes, as they become a game-changer in the pursuit of turbo excellence.”

- Understanding Charge Pipes: Their Role and Benefits for Turbo Performance

- Designing and Optimizing Charge Pipes for High RPM Turbos

- Real-World Applications: Success Stories of Charge Pipes Enhancing Turbo Performance

Understanding Charge Pipes: Their Role and Benefits for Turbo Performance

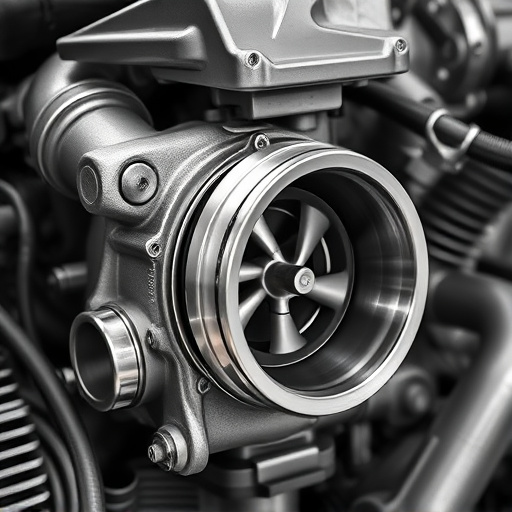

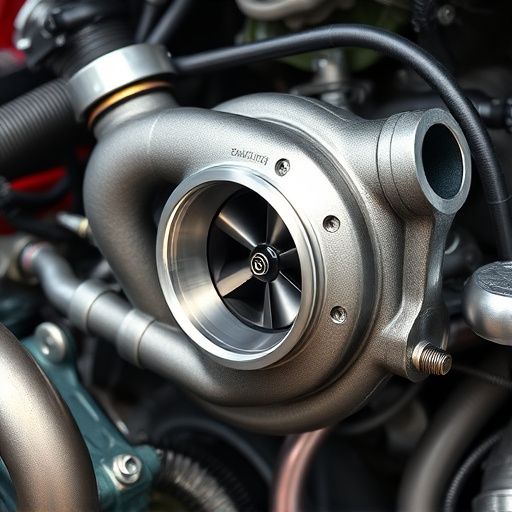

Charge pipes, an integral component of a turbocharged engine’s intake system, play a pivotal role in enhancing high RPM (revolutions per minute) performance. These pipes are designed to deliver air efficiently from the turbocharger to the engine, ensuring optimal combustion and power output during high-speed operations. By routing fresh, compressed air directly to the engine’s intake valves, charge pipes minimize restrictions and maximize airflow, which is crucial for maximizing horsepower and torque at higher RPMs.

The benefits of well-designed charge pipes extend beyond improved performance. They also contribute to better throttle response, reduced lag between turbo engagement and power delivery, and enhanced fuel efficiency. Unlike exhaust tips or brake pads/components that focus on waste products or braking systems, charge pipes directly impact the efficient extraction, compression, and utilization of air – fundamental elements for sustainable, high-performance engine operation.

Designing and Optimizing Charge Pipes for High RPM Turbos

Designing and optimizing charge pipes for high RPM turbos involves a delicate balance between airflow efficiency and pressure drop. Engineers must consider the turbine’s specific requirements, including inlet velocity, temperature, and pressure. Customized charge pipes, crafted from lightweight materials like aluminum or carbon fiber, are tailored to direct cool, dense air into the turbocharger, maximizing its potential power output.

The design process incorporates advanced computational fluid dynamics (CFD) simulations to model airflow patterns. This allows for precise adjustments in pipe diameter, bends, and fittings, ensuring optimal flow at high rotational speeds. Additionally, integrating performance air filters at strategic points can capture fine particles while maintaining low restriction, further enhancing turbocharger efficiency. These meticulously engineered charge pipes, when coupled with other high-performance parts like upgraded exhaust tips, contribute to a significant improvement in engine response and power delivery during high RPM operations.

Real-World Applications: Success Stories of Charge Pipes Enhancing Turbo Performance

In real-world applications, charge pipes have proven to be game changers for enthusiasts and professionals alike, showcasing their ability to significantly enhance turbo performance at high RPMs. These piping systems, carefully designed and tailored to specific vehicle setups, offer more than just improved flow; they provide a structured path for compressed air, ensuring efficient delivery to the engine’s combustion chambers. This direct route minimizes restrictions, allowing turbines to spin faster and produce more power, especially under demanding conditions.

Success stories abound, with many car owners and racing teams attributing their records and victories to optimized charge pipes. By integrating these components as part of a holistic approach, including suspension kits for enhanced handling and brake components for improved stopping power, they’ve achieved remarkable results. The combination of streamlined air flow, precision engineering, and advanced tuning has led to increased horsepower, better torque delivery, and overall performance that sets new standards in the high-RPM turbo landscape.

Charge pipes play a pivotal role in enhancing high RPM turbo performance, as evidenced by their successful real-world applications. By optimizing air flow and minimizing restrictions, these components ensure that turbos can operate at their peak efficiency during high-revving conditions. Understanding the design and benefits of charge pipes is crucial for any enthusiast or engineer looking to unlock the full potential of their turbocharged engine. Incorporating well-designed charge pipes into your setup can lead to significant improvements in power output and overall vehicle performance.