Charge pipes are vital for high-performance vehicles, optimizing airflow and engine efficiency by reducing backpressure and enhancing gas flow. Engineered with advanced CFD simulations, durable materials like stainless steel and aluminum, and rigorous testing, they ensure maximum flow, compatibility with other components, and longevity under extreme conditions.

Charge pipes, essential components in automotive systems, play a pivotal role in ensuring optimal engine performance. This article delves into the intricacies of these components, focusing on their design, functionality, and durability. We explore how engineers optimize charge pipes for maximum flow, employing innovative design principles. Additionally, we highlight critical aspects of material selection, testing, and longevity assurance, ensuring these vital parts withstand harsh conditions. Understanding these elements is key to enhancing overall system efficiency and reliability.

- Understanding Charge Pipes: Key Components and Functionality

- Engineering for Maximum Flow: Design Principles and Innovations

- Durability Considerations: Materials, Testing, and Longevity Assurance

Understanding Charge Pipes: Key Components and Functionality

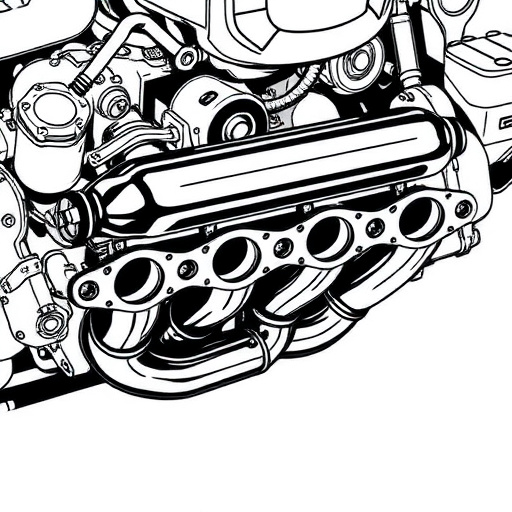

Charge pipes are a crucial component in any high-performance vehicle setup, designed to optimize airflow and enhance engine efficiency. These pipes, part of the broader exhaust system, facilitate the swift movement of gases, ensuring that the engine receives an ample supply of fresh air, which is essential for optimal combustion. By facilitating maximum flow, charge pipes contribute significantly to improved engine performance, particularly in vehicles equipped with powerful engines or those requiring enhanced aerodynamic capabilities.

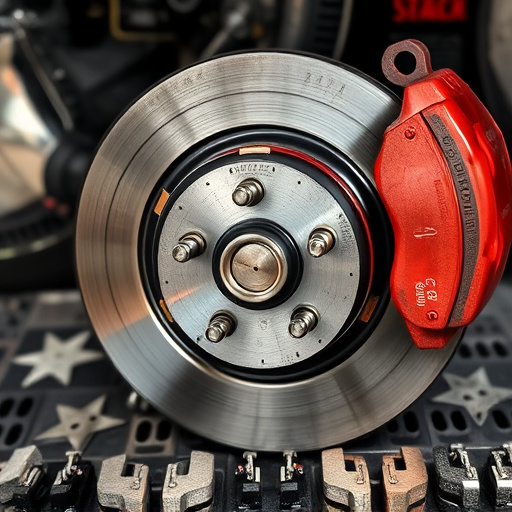

Key components of a charge pipe include high-flow headers, which collect exhaust gases from multiple cylinders, and smooth, optimized internal passages that minimize restrictions. This design allows for efficient gas flow, reducing backpressure and enabling the engine to breathe more freely. Often integrated with performance brakes and air filter kits or coilover kits, these pipes play a vital role in enhancing overall vehicle performance, ensuring drivers experience smoother acceleration and improved power delivery.

Engineering for Maximum Flow: Design Principles and Innovations

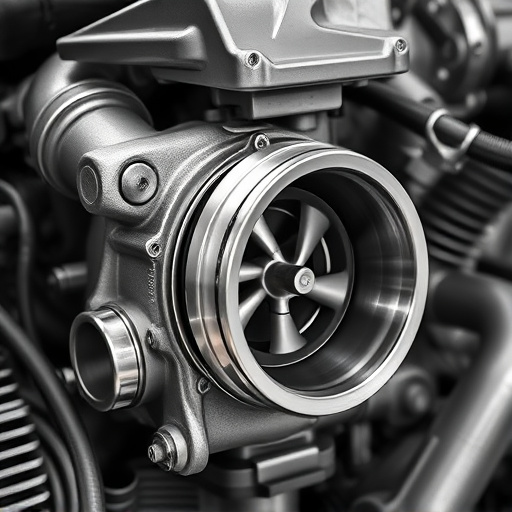

Engineers face a constant challenge when designing charge pipes—maximizing airflow while ensuring durability. To achieve this, modern design principles focus on several key areas. First, smooth and optimized internal geometry reduces turbulence, enabling more efficient flow. This is achieved through advanced computational fluid dynamics (CFD) simulations that model air behavior within the pipe.

Additionally, innovative materials and construction techniques play a significant role. High-strength alloys and advanced fabrication methods enhance durability, ensuring charge pipes can withstand extreme conditions, especially in performance vehicles where exhaust systems and suspension components operate under intense stress. These engineering advancements not only boost vehicle performance but also guarantee the longevity of critical components.

Durability Considerations: Materials, Testing, and Longevity Assurance

When designing charge pipes for maximum flow and durability, material selection is a key consideration. High-quality, corrosion-resistant metals like stainless steel and aluminum are preferred choices due to their longevity under intense conditions, ensuring they withstand the rigors of both high-performance engines and extreme environments. These materials not only prevent premature failure but also maintain optimal airflow, crucial for maximizing engine performance.

Rigorous testing plays a pivotal role in gauging the durability of charge pipes. Simulating real-world conditions through stress tests, pressure checks, and exposure to varying temperatures helps identify potential weaknesses. Additionally, ensuring compatibility with other essential automotive components, such as cold air intakes and suspension systems, is vital. Integrating these elements seamlessly prevents interference that could compromise performance or structural integrity, especially when combined with a well-designed cat back exhaust system. This holistic approach guarantees that the charge pipes not only last but also contribute to a seamless, efficient, and reliable vehicular setup.

Charge pipes, engineered with a focus on maximum flow and durability, represent a significant advancement in electrical system design. By understanding their key components, implementing innovative design principles, and ensuring robust materials and testing, these pipes offer long-lasting solutions for efficient current flow. As the demand for reliable and sustainable power distribution continues to grow, charge pipes are poised to play a pivotal role in shaping the future of electricity infrastructure.