Charge pipes, crucial for efficient intake of compressed air/fuel mixtures in engines, directly impact performance, power, and responsiveness, especially in high-performance vehicles. Upgrading these components optimizes airflow, reduces restrictions, enhances engine breathing, improves throttle response, and leads to increased horsepower, better torque across RPMs, and improved overall engine efficiency. In modern automotive tuning, upgrading charge pipes is vital for maximizing vehicle modifications, ensuring efficient air intake, and optimizing engine output, particularly in models designed to handle high PSI efficiently.

Charge pipes, integral components of engine systems, facilitate the efficient flow of compressed air, directly impacting performance. As vehicles evolve, demanding higher power outputs and improved fuel efficiency, the need to enhance charge pipe capabilities becomes evident. This article delves into the world of charge pipes, exploring their significance in engine performance and identifying common limitations. We present effective solutions for upgrading these components to handle increased pressure (PSI) demands, ensuring optimal engine functionality.

- Understanding Charge Pipes and Their Role in Engine Performance

- Identifying the Need for Upgrade: Limitations and Challenges with Current Charge Pipes

- Effective Solutions: Upgrading Charge Pipes for Higher PSI Handling

Understanding Charge Pipes and Their Role in Engine Performance

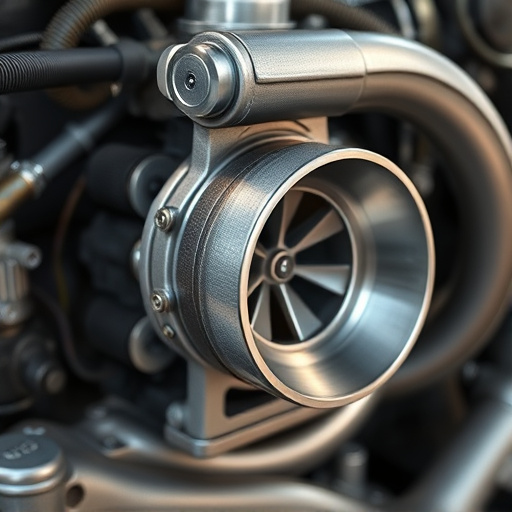

Charge pipes are an integral part of any internal combustion engine’s intake system. They serve as the conduit through which compressed air or fuel-air mixture flows from the turbocharger or supercharger to the cylinder head, playing a crucial role in engine performance and efficiency. The health and capacity of these pipelines directly impact the overall power output and responsiveness of the vehicle, especially in high-performance cars where peak PSI (pounds per square inch) is a key metric.

Effective charge pipe upgrades are essential for maximizing the potential of modern engines, particularly those equipped with forced induction systems like turbos or superchargers. Unlike stock charge pipes, which may be designed for adequate performance under average conditions, custom-engineered intake components, including upgraded charge pipes, can optimize air flow, reduce restrictions, and enhance engine breathing, resulting in improved throttle response, higher horsepower, and better torque across the entire RPM range—an advantage not only for enthusiasts but also for professional racing teams and those involved in modifying brake components for enhanced stopping power.

Identifying the Need for Upgrade: Limitations and Challenges with Current Charge Pipes

In the realm of automotive performance, upgrading charge pipes is a strategic move to enhance engine efficiency and overall vehicle dynamics. The current charge pipe systems, while functional, often face limitations that hinder their ability to meet the demands of modern high-performance vehicles. One of the primary challenges lies in their inability to handle increased air flow requirements, especially when paired with powerful engines and modified intake components like cold air intakes. These modifications generate more positive pressure inside the engine, demanding a robust charge pipe capable of withstanding higher pressure (PSI).

The limitations become more apparent during dynamic driving conditions, where rapid acceleration and elevated engine speeds put immense stress on the charge pipes. Standard pipes may struggle to maintain optimal air delivery, leading to performance setbacks and reduced engine responsiveness. This is particularly noticeable when combined with coilover kits that fine-tune suspension settings for enhanced handling. Upgrading to more robust charge pipes becomes essential to unlock the full potential of these modifications, ensuring efficient air intake and optimizing engine output.

Effective Solutions: Upgrading Charge Pipes for Higher PSI Handling

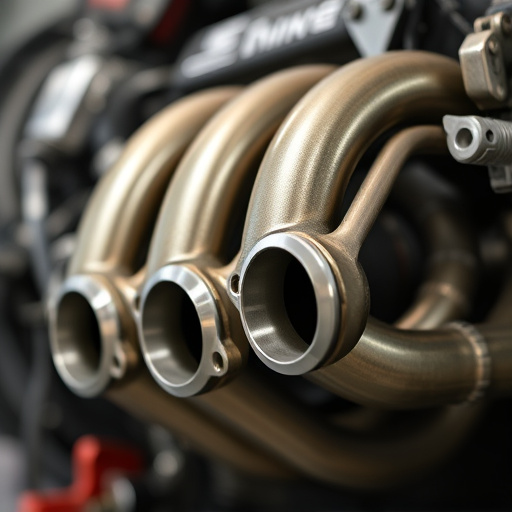

Upgrading charge pipes is a strategic move for vehicles designed to handle higher PSI (pounds per square inch) efficiently. This modification directly addresses the bottleneck often encountered in standard piping, allowing for better airflow and enhanced performance. By enhancing the charge pipe’s capacity, vehicles can process more air at high pressures, which is crucial for powerful engines.

Effective solutions involve selecting upgraded charge pipes designed with advanced materials and engineering to withstand higher PSI. These modern charge pipes often incorporate features like improved sealing mechanisms, reinforced walls, and optimized internal geometries to minimize turbulence and pressure drop. Integrating such upgrades alongside well-maintained exhaust mufflers and optimal brake components ensures a harmonious system that enhances both engine performance and overall vehicle efficiency.

Upgrading charge pipes is a strategic move to enhance engine performance, especially in high-pressure scenarios. By addressing the limitations of current designs, these upgrades ensure smoother, more efficient operations. This article has highlighted the critical role of charge pipes and offered practical solutions for handling increased PSI, ultimately contributing to improved overall engine functionality.