Charge pipes are essential in high-temp automotive environments, managing hot gases/fluids efficiently. They facilitate hot air flow from combustion chambers to turbochargers/superchargers, enhancing power and efficiency. Made of heat-resistant materials like stainless steel or titanium, these pipes offer superior thermal stability, corrosion resistance, and exceptional heat conductivity. Innovative designs include enhanced insulation and cooling mechanisms for optimal temp control, enhancing engine performance and durability in high-performance vehicles.

In the realm of high-performance vehicles, charge pipes play a vital role by efficiently transporting coolant across demanding systems. This article delves into the critical aspect of charge pipes’ thermal management, focusing on their ability to withstand elevated temperatures. We explore the materials science behind heat-resistant designs and highlight strategic approaches that enhance their durability. Understanding these innovations is essential for automotive engineers aiming to optimize engine performance while ensuring reliable charge pipe functionality in extreme conditions.

- Understanding Charge Pipes' Role in High-Temperature Environments

- Materials Science Behind Heat-Resistant Charge Pipes

- Design Strategies for Enhanced Thermal Durability in Charge Pipes

Understanding Charge Pipes' Role in High-Temperature Environments

Charge pipes play a pivotal role in high-temperature environments, serving as vital components in various automotive systems. These piping structures are designed to conduct and manage hot gases or fluids efficiently, ensuring optimal performance and safety. In vehicles equipped with powerful engines, charge pipes specifically facilitate the flow of hot air from the combustion chamber to the turbocharger or supercharger, a process crucial for enhancing engine power and efficiency.

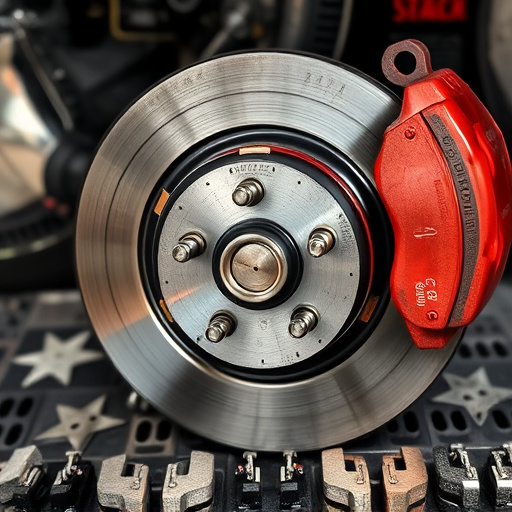

Beyond their primary function, robust charge pipes are essential in high-performance cars where extreme temperatures can be reached due to intense driving conditions. They must withstand not only the heat generated by the engine but also external factors like direct sunlight, ensuring stability and integrity over time. Unlike cold air intakes that require cool air for optimal performance, charge pipes focus on efficient heat transfer, complementing other components such as brake pads and muffler tips in high-temperature scenarios without compromising functionality or durability.

Materials Science Behind Heat-Resistant Charge Pipes

The materials science behind heat-resistant charge pipes is a fascinating blend of advanced engineering and precise metallurgy. These pipes are designed to withstand extreme temperatures, often found in high-performance vehicles with powerful engines. The key lies in selecting materials that offer exceptional thermal stability and resistance to oxidation and corrosion. In many cases, charge pipes are crafted from specialized alloys, such as stainless steel or titanium, known for their superior heat conductivity and durability.

Furthermore, the design incorporates innovative features like enhanced insulation and strategic cooling mechanisms. These modifications not only protect the pipes from intense heat but also ensure the efficient flow of charged air or exhaust gases. This is particularly crucial in systems like cold air intakes and performance exhaust, where optimal temperature control directly impacts engine performance and efficiency. By combining robust materials with clever design strategies, these charge pipes deliver top-tier functionality for various intake components.

Design Strategies for Enhanced Thermal Durability in Charge Pipes

To enhance the thermal durability of charge pipes, manufacturers employ several design strategies. One key approach is to incorporate high-temperature-resistant materials such as stainless steel or advanced alloys that can withstand extreme heat without degradation. These materials not only ensure the structural integrity of the charge pipe but also prevent premature aging or failure due to prolonged exposure to hot gases and fluids.

Additionally, designing charge pipes with optimized geometry plays a crucial role in thermal management. Strategically placed vents and cooling channels within the pipe allow for better airflow, reducing heat buildup. This is particularly important in high-performance vehicles where intake components like coilover kits and air intake systems generate significant heat. By efficiently dissipating this heat, the charge pipes maintain optimal operating temperatures, ensuring both efficiency and longevity.

Charge pipes, designed to withstand extreme temperatures, are essential components in demanding industries. Through a combination of advanced materials science and innovative design strategies, these pipelines ensure reliable performance in high-temperature environments. By leveraging heat-resistant materials and implementing thoughtful construction techniques, modern charge pipes offer enhanced thermal durability, making them indispensable for applications ranging from power generation to space exploration.