Charge pipes, critical for automotive high-performance applications, endure extreme temperatures through advanced materials like stainless steels and specialized alloys. They enhance efficiency in exhaust systems and intakes while also serving industrial power plants. Future developments aim to integrate lightweight composites, advanced cooling tech, and smart sensors for predictive maintenance, catering to faster speeds, powerful engines, and electric vehicles' growth.

Charge pipes, essential components in high-temperature systems, face stringent challenges in industrial settings. This article explores the critical role of heat-resistant charge pipes in managing extreme temperatures. We delve into the material science behind their design, examining innovative solutions for enhanced durability. Furthermore, it highlights practical applications and future trends, underscoring the ongoing efforts to optimize charge pipe performance. Understanding these advancements is crucial for professionals seeking efficient and reliable systems.

- Understanding Charge Pipes' Role in High-Temperature Environments

- Material Science Behind Heat-Resistant Charge Pipes

- Practical Applications and Future Trends in Charge Pipe Design

Understanding Charge Pipes' Role in High-Temperature Environments

Charge pipes play a vital role in automotive systems, especially in high-temperature environments. These components are responsible for transporting hot gases and fluids, such as exhaust gases from engine combustion or coolant circulating within the engine block. In vehicles designed for performance or racing, where engines operate at elevated temperatures, the reliability and durability of charge pipes become critical.

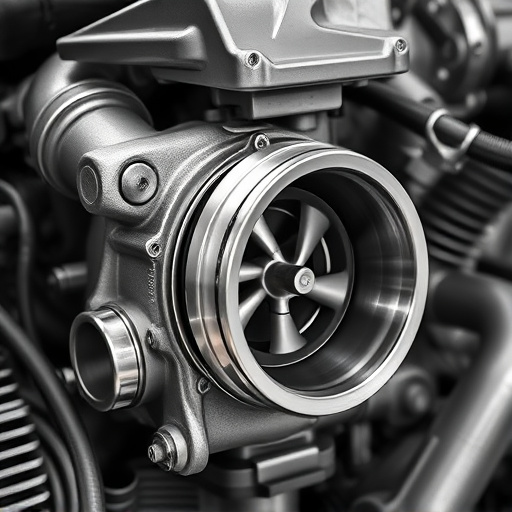

In these extreme conditions, charge pipes must withstand not only high temperatures but also rapid thermal changes. They are often exposed to intense heat from components like brake rotors during heavy braking or from a cat-back exhaust system. Moreover, intake components, which are closely connected to the charge pipes, also require robust materials and designs to prevent heat damage. Therefore, engineers focus on using advanced materials and innovative manufacturing techniques to ensure charge pipes can perform consistently without failure in demanding automotive applications.

Material Science Behind Heat-Resistant Charge Pipes

The material science behind heat-resistant charge pipes is a fascinating blend of advanced metallurgy and innovative design. These pipes are engineered to withstand extreme temperatures, often found in high-performance vehicles with powerful engines. The key lies in selecting and treating metals that possess exceptional thermal properties, such as high melting points and excellent heat conductivity. Stainless steels, for instance, are a popular choice due to their resistance to corrosion and ability to maintain structural integrity under intense heat.

Specialized alloys, often incorporating elements like chromium, nickel, and molybdenum, enhance the pipes’ durability. These alloys form robust bonds, improving the overall strength and stability of the pipe against thermal expansion and contraction. Moreover, advanced coatings and surface treatments can further boost heat resistance, protecting the charge pipes from environmental factors and ensuring optimal performance in both performance exhaust systems and cat back exhaust configurations. Even cold air intakes benefit from these materials’ prowess in handling high temperatures, maintaining efficiency and reliability.

Practical Applications and Future Trends in Charge Pipe Design

Charge pipes, designed to withstand high temperatures, find practical applications across various industries. These components are essential in automotive systems, especially for high-performance vehicles and racing cars, where they ensure optimal engine performance and efficiency. Moreover, their use extends to industrial settings, such as power plants and heavy machinery, where robust suspension components are necessary to handle extreme conditions. With advancements in materials science, modern charge pipes offer improved durability, enhanced heat dissipation, and reduced weight, making them key elements in the pursuit of higher engine outputs.

Looking ahead, future trends in charge pipe design focus on integrating advanced cooling technologies, incorporating lightweight materials like carbon fiber composites, and enhancing structural integrity to accommodate faster speeds and more powerful engines. As electric vehicles gain prominence, charge pipes tailored for high-voltage systems will become increasingly important. Additionally, the integration of smart sensors and connectivity features could enable real-time monitoring and predictive maintenance, ensuring optimal performance and longevity of these critical components in both traditional and alternative energy applications, including air filter kits designed for high-performance parts.

Charge pipes, designed to withstand extreme temperatures, have evolved from mere components to essential elements in high-performance systems. Advancements in material science have enabled the development of more durable and efficient charge pipes, catering to diverse industries’ needs. As we look towards the future, innovative designs and materials promise even greater resilience, ensuring these critical components can handle increasingly demanding environments. By continuing to explore and optimize charge pipe technology, engineers can drive progress across various sectors, solidifying their role as game-changers in high-temperature applications.