Charge pipes, vital automotive components, facilitate efficient fluid transfer under demanding conditions, especially in high-temperature environments like brake systems and cold air intakes. Manufacturers use advanced materials like stainless steel and aluminum alloys for their corrosion resistance and heat stability. For extreme temperatures, robust composites or specialized polymers are employed. Precise design and manufacturing techniques, including advanced welding and quality control, ensure these pipes withstand structural integrity challenges in applications like brake pads and air intake systems, enhancing driving safety and efficiency.

- Understanding Charge Pipes and Their Role in High-Temperature Applications

- Material Selection for Heat Resistance in Charge Pipes

- Design and Manufacturing Techniques to Ensure Durability at Extreme Temperatures

Understanding Charge Pipes and Their Role in High-Temperature Applications

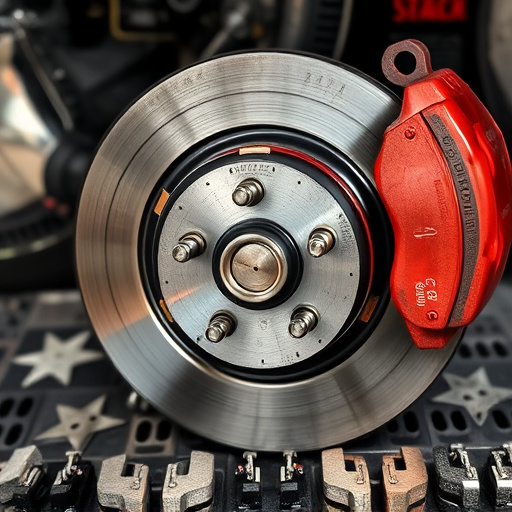

Charge pipes, integral components in various automotive systems, play a pivotal role in facilitating the efficient transfer of fluids, especially under extreme conditions. These pipes are designed to withstand high temperatures, ensuring optimal performance in applications such as brake components and suspension kits. In vehicles equipped with cold air intakes, charge pipes also serve as vital conduits, directing intake air efficiently while maintaining structural integrity under intense heat.

Understanding the importance of durability and reliability, manufacturers invest heavily in developing charge pipes that can endure harsh environments. Advanced materials and engineering techniques are employed to create robust pipelines capable of resisting thermal expansion and contraction, corrosion, and wear. This ensures not just the longevity of these components but also enhances overall system performance, contributing to safer and more efficient driving experiences.

Material Selection for Heat Resistance in Charge Pipes

When designing charge pipes to withstand high temperatures, material selection is paramount. The ideal material should offer superior heat resistance while maintaining structural integrity under extreme conditions. Inautomotive applications, for instance, stainless steel and aluminum alloys are popular choices due to their ability to resist corrosion and maintain their shape even when exposed to intense heat from exhaust systems or intercoolers. These materials’ high thermal conductivity also aids in dissipating excess heat, preventing pipe failure.

Furthermore, the selection should consider the proximity of the charge pipes to hot brake components, intake components, and performance air filters. Proximity to these can elevate the temperature of the pipes beyond their operating limit, necessitating the use of even more robust materials. Advanced composite materials and specialized high-temperature polymers are emerging options that promise enhanced heat resistance without compromising strength or flexibility, catering to the demands of modern automotive and performance engineering.

Design and Manufacturing Techniques to Ensure Durability at Extreme Temperatures

The design and manufacturing techniques employed for charge pipes are pivotal in ensuring their durability when exposed to high temperatures. Advanced engineering methods focus on creating robust pipe structures using high-grade materials like stainless steel and specialized alloys that can withstand extreme conditions. These materials offer superior heat resistance, minimizing the risk of damage or degradation even in the harshest environments.

Manufacturing processes involve precise techniques such as advanced welding technologies and tight quality control measures to ensure structural integrity. Specialized coatings and treatments may also be applied to further protect against thermal stress and corrosion. This meticulous approach guarantees that charge pipes not only endure high temperatures but also maintain optimal performance, ensuring reliable operation in various applications, including those involving brake pads, air intake systems, and air filter kits.

Charge pipes, designed to withstand high temperatures, are essential components in demanding industrial applications. By understanding their critical role, selecting suitable materials, and employing advanced manufacturing techniques, these pipelines can reliably perform in extreme conditions. This ensures the safety and efficiency of processes requiring robust heat resistance, making charge pipes a game-changer in various sectors.