Charge pipes are essential components in turbocharging systems, facilitating compressed air flow from turbochargers to engines, enhancing performance and reliability. Poor quality charge pipes can restrict airflow, decrease power output, and lead to turbo failure. Regular maintenance, including inspecting and replacing worn parts, prevents damage from extreme conditions, ensuring optimal engine health and extending turbocharger lifespan.

Charge pipes, a vital component in turbocharging systems, play a crucial role in engine performance and efficiency. These components deliver compressed air from the turbocharger to the engine, enhancing power output. However, poor-quality charge pipes can lead to significant issues, affecting both engine performance and turbo reliability. Regular maintenance and ensuring high-quality charge pipes are essential practices for optimal turbo operation, preventing costly repairs and maximizing vehicle performance.

- Understanding Charge Pipes: Their Role in Turbo Systems

- The Impact of Poor Quality Charge Pipes on Engine Performance

- How Regular Maintenance Ensures Reliable Turbo Operation with Charge Pipes

Understanding Charge Pipes: Their Role in Turbo Systems

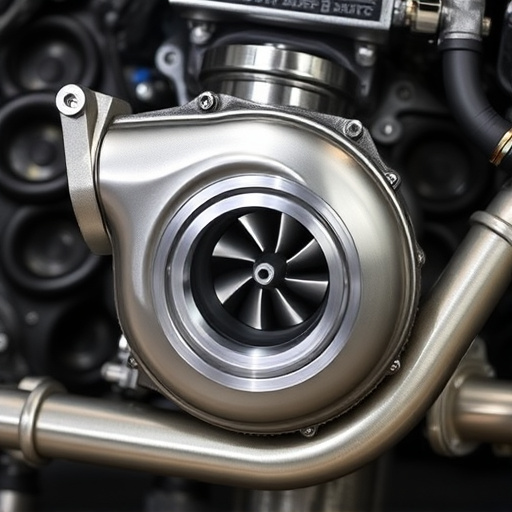

Charge pipes are an integral component within turbocharging systems, responsible for transporting compressed air from the turbocharger to the engine’s intake manifold. Their primary role is to ensure a seamless and efficient flow of air, which is essential for optimal engine performance and power output. These pipes form a crucial link between the turbocharger’s compressor and the rest of the vehicle’s induction system, including the air intake systems and cat-back exhausts.

The significance of charge pipes lies in their ability to maintain pressure differentials across the turbocharger. By providing a direct route for compressed air, they minimize restrictions and losses, ensuring that the engine receives a consistent supply of rich, high-pressure air. This is particularly vital during rapid acceleration or under heavy load conditions when the demand for increased power is highest. Properly designed charge pipes, often enhanced with advanced materials and engineering, contribute to overall turbo reliability, enabling smoother operation and maximizing the potential of the turbocharged engine.

The Impact of Poor Quality Charge Pipes on Engine Performance

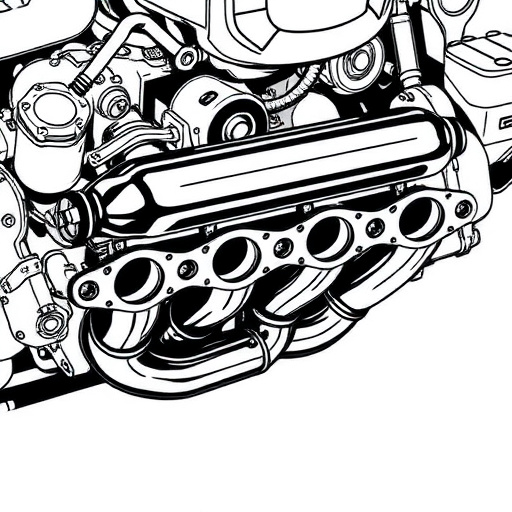

Poor quality charge pipes can significantly impact engine performance and overall reliability, especially in turbo-charged vehicles. These pipes are a vital component of the vehicle’s induction system, responsible for delivering compressed air from the turbocharger to the engine. When charge pipes are subpar, they can restrict airflow, leading to reduced power output and efficiency. This is particularly noticeable during high-performance driving scenarios where peak horsepower and torque are demanded.

Additionally, low-quality charge pipes may contribute to uneven air distribution within the engine, causing uneven combustion. Over time, this can result in increased wear and tear on turbocharger components, potentially leading to premature failure. Unlike aftermarket suspension kits or exhaust tips, which enhance aesthetics or sound, well-designed charge pipes are essential for maintaining optimal engine health, ensuring smooth power delivery, and extending the lifespan of the expensive turbocharger.

How Regular Maintenance Ensures Reliable Turbo Operation with Charge Pipes

Regular maintenance plays a pivotal role in ensuring the reliable operation of turbos, and charge pipes are at the heart of this process. These pipes are responsible for delivering compressed air to the turbocharger, which in turn enhances vehicle performance. By conducting routine checks and services, including inspecting and replacing worn-out charge pipes, mechanics can prevent potential issues that may lead to turbo failure.

Maintaining charge pipes is crucial because they are susceptible to damage from various factors, such as extreme temperatures, pressure differentials, and exposure to corrosive elements. Regular maintenance involves checking for leaks, ensuring proper alignment, and replacing any damaged or outdated components. This proactive approach not only preserves the integrity of the turbo system but also contributes to overall vehicle health, especially when combined with well-maintained suspension kits and top-tier brake components.

Charge pipes play a pivotal role in turbo system reliability, ensuring optimal engine performance. Their quality and regular maintenance are paramount to prevent issues that can compromise both engine health and efficiency. By understanding the critical functions of charge pipes and implementing routine upkeep, vehicle owners can navigate the complexities of turbocharging with confidence, knowing their engines are powered by dependable components.