Charge pipes, through counterflow cooling and optimized air induction, enhance combustion efficiency and power output in vehicles and industrial machinery. They integrate with exhaust systems for minimal modifications yet significant performance boosts, offering improved fuel efficiency and lower emissions. Their versatility makes them a preferred choice across sectors.

In today’s pursuit of enhanced performance, industries are constantly seeking innovative solutions to optimize airflow. One such game-changer is the implementation of charge pipes, a technology revolutionizing air density and pressure regulation. This article delves into the dynamics of airflow, explores the fundamental principles behind charge pipes, and highlights their multifaceted benefits across diverse sectors. By understanding these advanced systems, businesses can harness the power of efficient air management for improved operational excellence.

- Understanding Airflow Dynamics and Limitations

- Introduction to Charge Pipes: Basic Principle

- Benefits of Implementing Charge Pipes in Various Industries

Understanding Airflow Dynamics and Limitations

Understanding Airflow Dynamics and Limitations

Airflow dynamics play a crucial role in enhancing engine performance, especially when it comes to charge pipes. These components are designed to optimize air intake, ensuring a steady and dense supply of air reaches the engine. By improving airflow, vehicles equipped with charge pipes can achieve better combustion, resulting in increased horsepower and torque. The strategic placement and design of these pipes allow for smoother air flow, reducing turbulence and minimizing pressure drop, which is essential for maximizing performance potential.

However, it’s important to recognize that there are limitations to what charge pipes can achieve. Factors such as vehicle aerodynamics, engine size, and the overall exhaust system can influence airflow capabilities. Additionally, while performance air filters and performance exhaust systems complement charge pipes by further enhancing filtration and backpressure reduction respectively, they do not substitute for well-designed charging solutions. Understanding these dynamics is key to optimizing engine performance in conjunction with charge pipe installations.

Introduction to Charge Pipes: Basic Principle

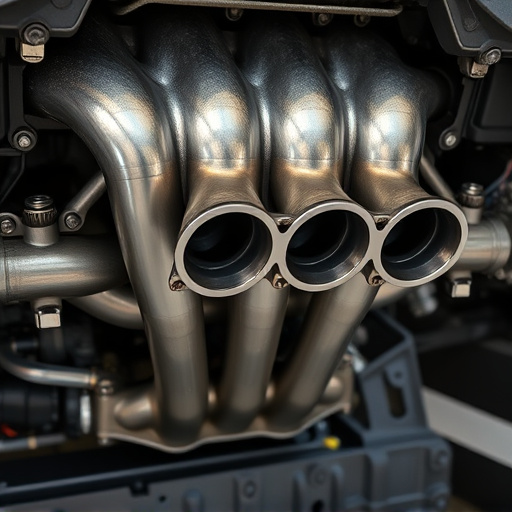

Charge pipes, a relatively recent innovation in automotive engineering, are designed to optimize exhaust gas flow, enhancing air density and pressure within the engine. This simple yet powerful concept involves rerouting a portion of the exhaust gases back into the combustion chamber during the intake stroke. By reintroducing these gases, charge pipes increase the overall air-fuel mixture, leading to improved combustion efficiency and power output.

At their core, charge pipes operate on the principle of counterflow cooling, where hot exhaust gases are directed backward to cool incoming fresh air. This process allows for a more efficient burn and better utilization of available oxygen, resulting in increased engine performance. Often integrated with specialized muffler tips or exhaust systems, these pipes offer a straightforward way to boost an engine’s capabilities without extensive modifications.

Benefits of Implementing Charge Pipes in Various Industries

Implementing charge pipes offers a myriad of benefits across diverse industries. By optimizing air induction, these innovative components enhance engine performance in vehicles and industrial machinery. Charge pipes ensure a more efficient and consistent flow of air, leading to improved combustion and increased power outputs. This is particularly advantageous for high-performance exhaust systems, where the right intake components can significantly boost engine response and overall vehicle dynamics.

Moreover, charge pipes contribute to reduced backpressure in the intake system, minimizing the restrictions that commonly plague traditional exhaust mufflers. This design allows for better air compression, resulting in higher fuel efficiency and lower emissions. Their versatility makes them a popular choice not just for automotive enthusiasts seeking performance upgrades but also for industries requiring reliable and robust solutions for their machinery’s breathing systems.

Charge pipes have emerged as a game-changer in optimizing airflow dynamics, offering increased air density and pressure. By understanding the basic principle behind these innovative systems, various industries can harness their benefits, leading to enhanced performance and efficiency. Implementing charge pipes is not just a technological advancement; it’s a strategic move towards better control of air movement, ensuring optimal processes across different sectors.