Aluminum charge pipes outperform silicone alternatives with their superior weight savings, durability, corrosion resistance, and thermal conductivity. These benefits translate into improved vehicle performance, fuel efficiency, and handling. Their strength-to-weight ratio allows for easier routing and intricate designs in exhaust and intake systems. Automotive manufacturers embrace aluminum charge pipes for these advantages, while car enthusiasts use them to enhance their vehicles' performance potential.

“Unveiling the superior performance of aluminum vs. silicone charge pipes, a key component in modern vehicle engineering. This article delves into the strategic advantages of each material, highlighting their unique benefits. Aluminum offers significant weight savings and enhanced durability, improving fuel efficiency and vehicle performance. Silicone, on the other hand, stands out for its flexibility and exceptional temperature resistance, simplifying installation and ensuring reliable operation. We explore these materials’ impact on charge pipe performance and gain insights from real-world applications.”

- Aluminum Charge Pipes: Lightweight and Durable Advantages

- – Discussion on the weight savings compared to silicone

- – How aluminum's strength-to-weight ratio benefits vehicles

Aluminum Charge Pipes: Lightweight and Durable Advantages

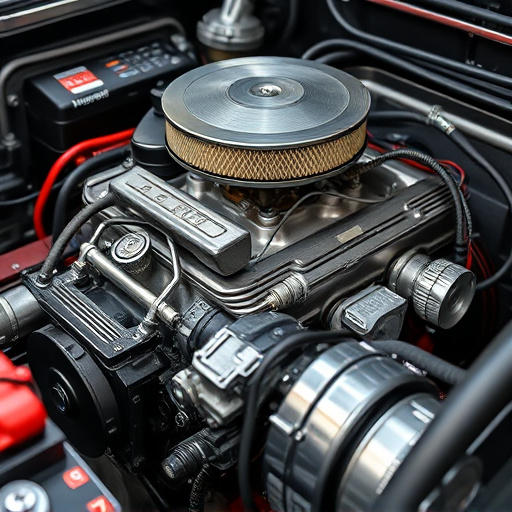

Aluminum charge pipes offer several advantages over their silicone counterparts, particularly when it comes to weight and durability. This lightweight metal is renowned for its exceptional strength-to-weight ratio, making it an ideal choice for automotive applications. In the context of charge pipes, this translates into significant benefits. By using aluminum, vehicle manufacturers can reduce overall weight, which has a positive impact on fuel efficiency and performance.

Additionally, aluminum is highly resistant to corrosion, ensuring that these components maintain their integrity over time, especially in demanding environments. Unlike silicone, which can degrade under extreme conditions, aluminum charge pipes are designed to withstand high temperatures and pressure changes associated with high-performance parts and cold air intakes. This longevity not only extends the life of the parts but also reduces the need for frequent replacements, ultimately saving costs for car enthusiasts who rely on their vehicles’ performance potential, often enhanced by air filter kits.

– Discussion on the weight savings compared to silicone

Aluminum charge pipes offer a significant advantage over their silicone counterparts when it comes to weight savings. This lighter construction is particularly beneficial for vehicles focused on performance, where every gram counts. Unlike silicone, aluminum is inherently more robust and durable, able to withstand extreme temperatures and pressures associated with high-performance exhaust systems without compromising its structural integrity. This strength-to-weight ratio translates directly into improved vehicle handling, acceleration, and overall driving dynamics.

The reduced weight of aluminum charge pipes can also have a positive impact on fuel efficiency. Lighter components mean less overall weight for the vehicle, leading to lower fuel consumption and better range. Additionally, aluminum’s superior thermal conductivity helps manage heat buildup within the exhaust system, keeping critical brake components cooler and ensuring consistent performance of other essential parts like brake pads, ultimately contributing to enhanced safety and control.

– How aluminum's strength-to-weight ratio benefits vehicles

Aluminum’s remarkable strength-to-weight ratio offers significant advantages for vehicles, especially when it comes to charge pipes. This lightweight metal can withstand substantial force while remaining remarkably thin and flexible, allowing for easier routing and reduced weight in exhaust systems and intake components. By incorporating aluminum charge pipes, automotive manufacturers can achieve several benefits. First, the lower weight of these pipes contributes to improved fuel efficiency as the vehicle’s overall mass is decreased, leading to better performance and reduced emissions. Second, the flexibility of aluminum enables more intricate designs, allowing for optimized air flow in exhaust mufflers and enhanced gas exchange in intake systems.

In conclusion, aluminum charge pipes offer significant advantages over silicone in terms of weight savings and durability. Aluminum’s superior strength-to-weight ratio makes it an ideal choice for vehicle components, contributing to improved performance and efficiency. When considering the benefits discussed, it’s clear that aluminum charge pipes are a game-changer in the automotive industry, providing both structural integrity and lightweight construction.